Super Hobs & Braches Pvt. Ltd. offers services for Resharpening of all types of indigenous as well as imported Gear Shaving Cutters on state of the art CNC GEAR SHAVING CUTTER GRINDING MACHINE.

Standard Involute, Tip Relief, Profile & Lead Crowning, "K" Profile & Special Profiles as per requirements of the customer can be provided. Lead and Profile graphs done on Klingelnberg P26 CNC Tester can be provided with every individual tool.

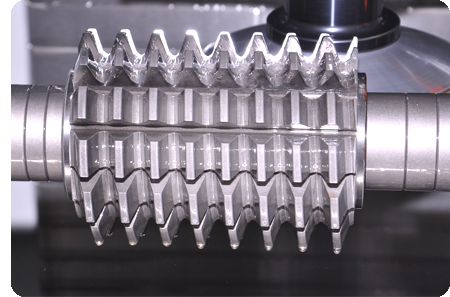

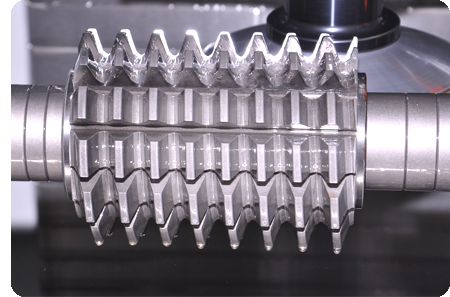

Hob Resharpening

The performance of hob is very much affected by the type of resharpening carried out. If a hob is resharpened under incorrect working condition, it may at times result in tooth breakage. So for hobs to perform better, weoffer highly accurate and precise resharpening of hobs on our state of the art CNC hob sharpening machine which can sharpen hobs upto "AAA" class.

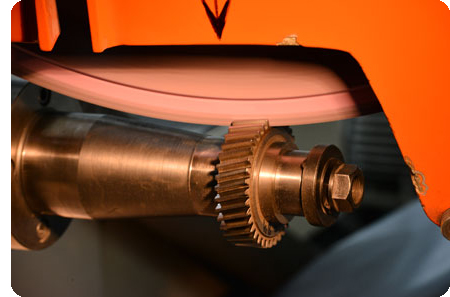

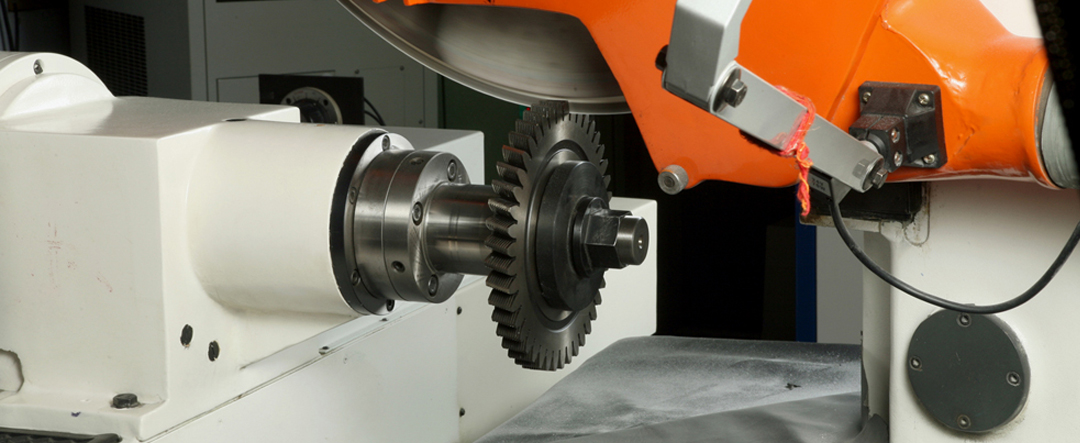

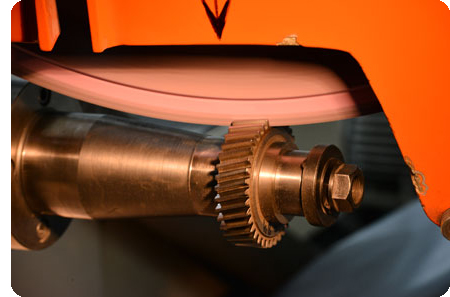

Master Gears Reprofiling

Master Gears become unusable after continuous use these tools can be reused after correction of Profile and other parameters and become as good as new.

We can reprofile your master gears on state of the art CNC Profile grinding Machine in Shortest possible time. Profile correction can be done as per your requirements. Lead and Profile graphs done on Klingelnberg P26 CNC Tester can be provided with every individual tool.

PVD Coatings

PVD coatings (Physical Vapour Deposition) are applied on cutting tools to extend the lifespan of the tools many times over. The choice of cutting tool coating is depending on the kind of cutting tool and its use. SHB offers following coating services:

- TiN

- TiCN

- TiAlN (Futura)

- AlCrN (Alcrona)

Benefits of Surface PVD coatings include:

- Longer tool life - 300% to 1000% increases are typical compared to uncoated

- Increased productivity - tools can be run at higher feeds and speeds

- Uniform thickness - will not alter critical dimensional tolerances of components or parts

- Corrosion resistant - thermally and chemically stable

- Smoother work piece surfaces - one half the co-efficient of friction of uncoated surfaces results in better surface finish in machining and better mold release in casting operations

- Lower maintenance costs - the significant increase in tool life means fewer tool changes and less down time

- More regrinds possible due to the wear land being significantly reduced on coated tools

LEAVE A COMMENT